Our Customer Collaboration interviews seeks to highlight our customer successes, and challenges, so that we can share lessons learned and wisdom gained with other railroad professionals.

Thinking of how to provide your staff life-like experience on critical tasks, reducing errors and fines – without additional rolling stock, instruction, and travel? Then read on.

In this interview, we speak with Harley Goodnoe, Director of Rail Operations at Conrad Yelvington Distributors to learn common training challenges that short line and regional railroads encounter — including limited classrooms, need for rolling stock, and difficulty of knowledge transfer. Heartwood’s Jess Cloutier-Carneiro joined Harley in this discussion.

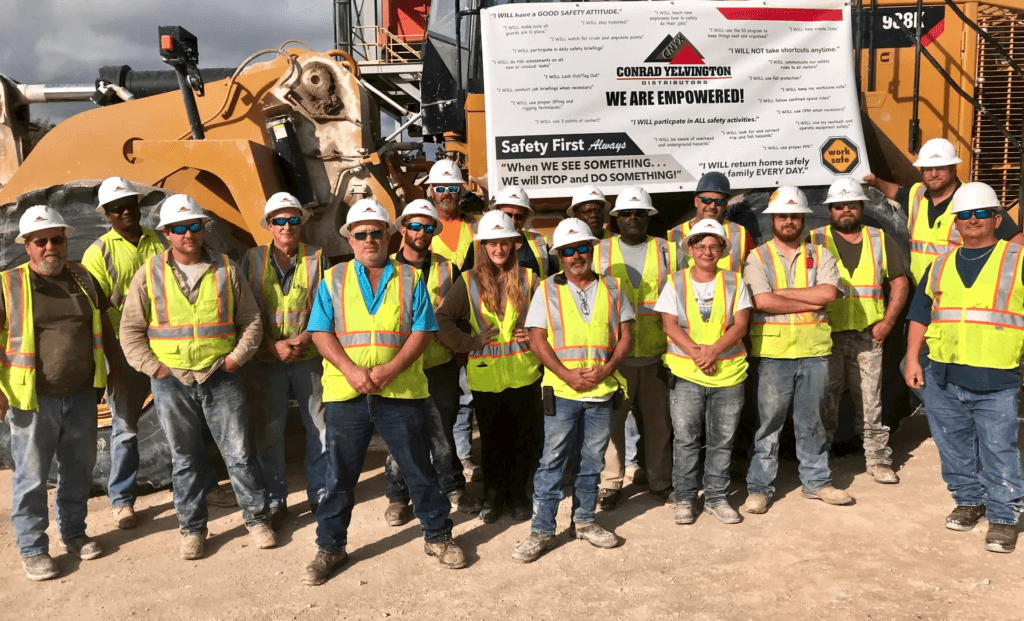

Conrad Yelvington Distributors is the largest distributor of aggregate in Florida, moving 5+ million tons annually through their network of over 30+ rail served terminals across Florida, South Carolina, Alabama, and Mississippi.

Conrad Yelvington Distributors is the largest distributor of aggregate in Florida, moving 5+ million tons annually through their network of over 30+ rail served terminals across Florida, South Carolina, Alabama, and Mississippi.

Jess Cloutier-Carneiro for Heartwood (HW): Can you tell us a little bit how your training and your education program were organized?

Harley Goodnoe: We currently have a rail operations safety training center here in Orlando. We can hold about 20 students at one time, with an FRA pool of about 115. This center processes training for engineers, qualify track inspectors, DSLE designated supervisors, and locomotive engineers that we’re using for our testing officers.

And we do all that here in Orlando, Florida.

HW: And how were your employees trained before using virtual training? What limitations did you encounter?

Harley: It took about a week for us to get through initial classroom training here in Orlando, but it was difficult to get employees out there. We require craft training with minimum time requirements. However, as you know, every individual is different with each individual learning at a different pace and capacity, and every terminal is different.

We found that we were getting some inconsistencies as it related to hands-on training. You know, we would spend a couple days here in Orlando with the students going over some hands-on, and then we would turn them over to the terminals. They’d go back to their home terminal and we the knowledge fell off once they reached these terminals.

HW: How was training conducted? How did you show your employees defects on your equipment?

Harley: It was really a talking process and we got an old rail car out here for the brake test that we would go over stuff like that, but it wasn’t near like it is now. It changed exponentially since we started using your simulation. We’ve added some days to the training process, but I think honestly, we’ve recouped that in the amount of time lost otherwise.

HW: How do you mean?

Harley: Before, we had a little checklist of things to look for and we went through and each class is different. But they’re just better prepared now when they leave the training center.

They’re better educated when they go out into the field, when they leave the training center here and they go out into each one of their respective terminals of operation, they’re just better prepared. They understand the verbiage, they understand what they’re looking at, they understand what they’re looking for.

HW: How did you implement virtual training at CYD?

Harley: We purchased iPads and we got about roughly 10 of them, because we can put 20 individuals in class and then they pair up.

My department spent about a month just familiarizing ourselves with the programs and I wanted to make sure that my managers of rail operations were very well versed. And then we started bringing our people in. Currently to date this year, we’ve done just over 20 initial certifications for both conductor and engineer.

Then we’ve done about 35 recertifications, based on CFR240 and 242 engineer and conductor programs.

HW: Any challenges while implementing virtual training? What about those that aren’t familiar with the technology?

Harley: That’s really good question actually, because I’m pretty much technologically challenged too.

But I’m going to be honest, it’s so easy to use Heartwood’s virtual training simulations that, and I don’t want to downplay the intricacy associated with the simulators, but its not overly hard to use, you know?

We don’t have any problems with it, to be honest with you. We haven’t even seen technology use as a challenge since we’ve began using the apps.

HW: Have you expanded the use outside of your core training needs? Have you used virtual training throughout your railroad?

Harley: So we don’t just use the sims for our conductors and our engineers, we also use them with our mechanical department. Our locomotive mechanics and two car shops, with a third fixing to come online.

We have the airflow simulator as well as the the CFR229 inspection simulator. We open that to our mechanical guys and we bring them in. With this training they are more knowledgeable, and they understand how to better articulate it to our engineers if they are having a problem.

HW: How is this better for operations?

Harley: We have six or seven locomotive mechanics, but we’ve got 30 terminals. A lot of times they’re trying to diagnose over the phone. Now, our mechanics and our engineers have a better understanding so that the two of them can get on the same page that much quicker.

HW: What is your workforce feedback after using virtual training?

Harley: We’ve gotten tremendous feedback from our people on it once they’ve left the training center. So we’re trying to get it out to everybody.

This interview was part of a larger webinar, which you can watch here.

Looking to upskill your agile railroading staff with scenario-based learning on 6 railcar types, 11 brake types, 30+ defects on your current systems – PCs, tablets or LMS? Heartwood’s packaged suite of apps starts at 50+ users. On your devices. In 30 days.

Reach out here – [email protected] or call 888.781.0274 ext. 701