Technological Advances are Subtle, Everywhere and Steaming Toward Railroads

Railroads have been chugging right along in recent years, keeping pace with technological advances as they appear on their radar. Even as they recognize shifts emerging just beyond the horizon, they’re increasingly open to adopting new modes, methods and operational considerations. This is great news. But there are still some general challenges to address; ways to further enhance safety and increase ROI – and we’ll detail them below!

Specifically, we’ll explore the speed at which the identification, recognition and adoption of new technologies is taking place – and how that needs to change. Technological advances are often subtle and are popping up at an increasingly accelerated rate, so railroads are left wondering which tracks make sense to explore. This can lead to lengthy indecision to see what others in the industry adopt and then it’s a feast or famine scenario, with efforts stagnating and opportunities missed. We have an overview of the current situation, as well as tips for moving forward follows!

Tracking Technological Advances & Opportunities

Railroads are innovative and forward-thinking, which has been proven time and again historically. Developing transcontinental services and transitioning from steam to diesel, while working through countless barriers and rethinking processes is par for the course. Granted, that switch happened over a twenty-year period, but it possibly had the most significant impact on transportation since the switch from horse-drawn carriages to steam in the 1830s (in the U.S., that is – the UK made this change approximately 30 years earlier).

And as we look at each successive, innovative change, we see that they happened progressively quicker due to the increasing sophistication of the ideas put forth. Impacts from these advances were felt across the country. This makes sense, as revolutionizing the power source in any industry has a ripple effect, naturally, particularly when the industry is responsible for transporting goods!

And as we look at each successive, innovative change, we see that they happened progressively quicker due to the increasing sophistication of the ideas put forth. Impacts from these advances were felt across the country. This makes sense, as revolutionizing the power source in any industry has a ripple effect, naturally, particularly when the industry is responsible for transporting goods!

Keeping up with that standard, as the bar is consistently raised, railroads are meeting today’s technological innovations with a level of sophistication and informed understanding around the potential ripple effects that these changes promise. It’s an exciting time to work in transportation because of it.

There are still challenges railroads are facing in this adoption though, as technological advances have begun to outpace the industry’s appetite for change. It’s a natural progression and one we need to confront, as we stand at the incline of this technological curve.

Keeping Pace with Cost Efficiencies & Safety Improvements

In light of COVID, as the world shut down and our new normal commenced, railroads found themselves benefitting from two well-timed initiatives: positive train control (PTC) and precision scheduling. Each worked on different, complementary components of operations and offered the ability to have fewer workers engaged in train operations.

Thanks to the Rail Safety Improvement Act of 2008 (RSIA), Positive Train Control were mandated a decade ago. PTCs are made up of “technologies designed to automatically stop a train before certain accidents related to human error occur. . . . [consisting of ] Hundreds of thousands of components, [forming] an interconnected network of freight, passenger and commuter railroads.”

And then Precision Scheduled Railroading (PSR) focused on operating with fewer workers managing much more efficiently running operations, with excess miles cut by reducing or eliminating underutilized stops and terminals. Fewer in-person workers also reduced the risk of spreading infection – but it also made the threat of infection much more potent when it happened.

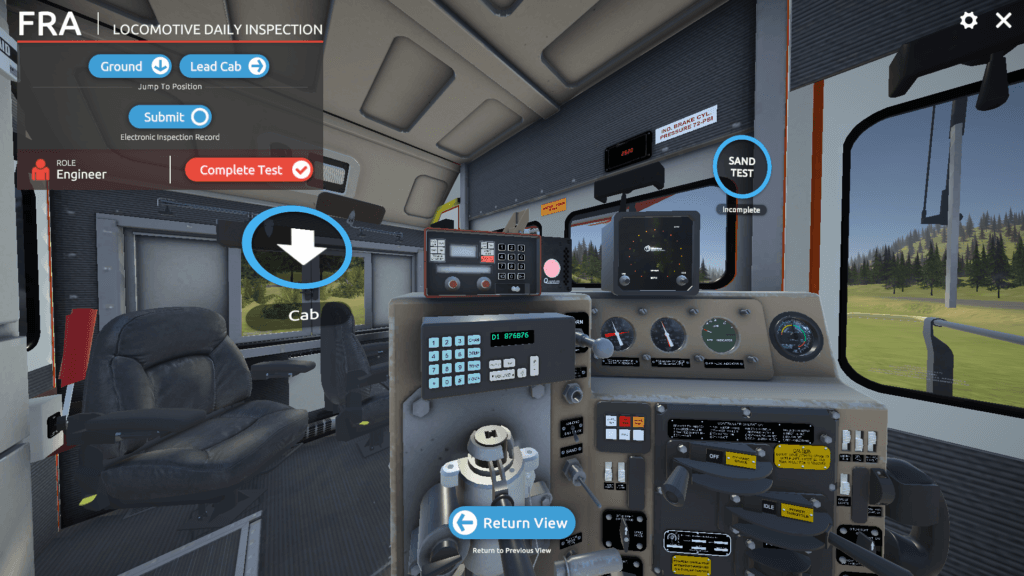

At the same time, many railroads were also exploring advances in simulation-based education tools. This was an exceptional assist as it allowed those PSR operations to have workers who were able to immediately understand additional functions and expertly step into related roles as needed. Using these simulations, workers are able to learn on any craft anytime, anywhere – and at the precise skill level they possess in each.

And this is where the real potential – and future for railroads – lies. Technological advances that demonstrate value in not only enhancing productivity, but also safety.

For example, although this piece explores the need (or not) for train guards, the thrust of the article revolves around the many ways in which technological advances have shifted operational requirements and made railways safer.

“There are clear opportunities to embrace all types of new technology to improve safety,” added Claire Coward, communications officer at independent company Rail Safety and Standards Board (RSSB). “Indeed, if you look at the history of the development of the railways over the last 200 years, the increase in technological capability and application has coincided with vast improvements in safety and a marked reduction in risk to passengers and the workforce.”

Are railroads naturally progressing to simulation-based education as the next step in their evolution? Well, many have!

Simulation-led education as the Next Technological Modernization for Railways

We know that enhanced access to information and modern education tools makes railways safer and offers exceptional long-term ROI, as there are many case studies available today speaking to this precise phenomenon.

The struggle we see often lies on a misalignment of understanding that views the trainer as an unessential part of the simulation-based educative process. This couldn’t be further from the truth.

The struggle we see often lies on a misalignment of understanding that views the trainer as an unessential part of the simulation-based educative process. This couldn’t be further from the truth.

Railroad educators play a more significant role than ever in implementation, but it’s one that needs to shift from ‘educator at the front of the room and in the field’ while maintaining other responsibilities, to ‘facilitator interacting in-person and virtually.’

The educator assesses the curriculum themselves and ensures they are capturing the information that railroads wish to transmit – and this is an ongoing process. The instructor also ensures the workers continue moving forward; s/he demonstrates skills in the field; and, also answers questions that a simulation cannot – advanced questions that require expertise and careful consideration to offer the best, nuanced answers.

And then these same individuals are also essential as they’re the first line of defense when it comes to identifying areas that require a course correct. These instances can happen so quickly and be lost in the shuffle without someone available who is committed to capturing those ‘once in a lifetime’ scenarios and recording feedback that ensure that whatever it is, it doesn’t result in a costly tragedy that could have been avoided.

Simulation tools complements on-the-job training and skill building, it doesn’t replace it. They make enhanced safety and exceptional ROI not only possible, but the next evolution of the industry. Considered in that light, it’s a hard option to pass up.

And it’s one we very much enjoy talking through with you on the phone or via email.

The future of railroading awaits!

Recognizing the ROI and safety value simulations offer, we’ve created training for BNSF, Amtrak, Union Pacific, CSX, Norfolk Southern, Kansas City Southern, and more. Reach out and we can help you implement simulation solutions.