This is part two of our series highlighting strengths and pitfalls of three very distinct training methods, relayed by way of The Three Little Pigs analogy. Every training progresses through the same basic stages, from design through to implementation, but the pedagogy, mode of training and the corresponding retention that results offer very dissimilar results – much like the fate of the three little pigs. The construction of the training is important.

This is part two of our series highlighting strengths and pitfalls of three very distinct training methods, relayed by way of The Three Little Pigs analogy. Every training progresses through the same basic stages, from design through to implementation, but the pedagogy, mode of training and the corresponding retention that results offer very dissimilar results – much like the fate of the three little pigs. The construction of the training is important.

Our stick house training has been around for a while. At its base, we find a somewhat solid foundation supporting a small, model home. Additions jut out in various directions, extending the space, modernizing and expanding its offering in places, while maintaining its original, stodgy design in others. No one likes spending time in the older parts of the house and go to great lengths to avoid them. Those areas of training are reminiscent of straw dwellings, and technicians forced to train in those rooms, leave feeling like they just wasted a whole bunch of time, because they did.

There are quite a few folks who recognize this struggle though, and work to change it when the needs of the organization are periodically reviewed, at least once each year. And during this time, stick house architects evaluate arguments around which training to revise and why, which training to scrap, and then, if there’s any budget left over – they run through their wish list and select a new training or two to begin building. This is where the building addition ideas are born, and the time architects spend on these efforts make the tedious revisions worthwhile.

A learning fixer upper

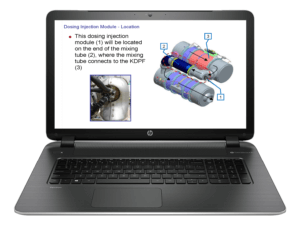

The revised training areas are instructor-led with printed manuals for participants to follow along, or they’re CBT (computer-based training: offering technicians the ability to complete training on their own time at a desk), and much of the training has a second part with a hands-on component, intended to put the manual/CBT learning through its paces. The oldest training sections, and the ones technicians truly despise and learn least from here, aren’t the instructor-led pieces – they’re the CBTs. Although the idea of technology and the freedom to work at a desk (their own or in a lab) was a good one, its delivery is dry and retention is actually lower than straw house rates. The instructor-led, interaction offered in straw constructions (albeit “unofficial”) is still interaction and it, as well as hands on training, trumps merely reading and clicking any day.

The revised training areas are instructor-led with printed manuals for participants to follow along, or they’re CBT (computer-based training: offering technicians the ability to complete training on their own time at a desk), and much of the training has a second part with a hands-on component, intended to put the manual/CBT learning through its paces. The oldest training sections, and the ones technicians truly despise and learn least from here, aren’t the instructor-led pieces – they’re the CBTs. Although the idea of technology and the freedom to work at a desk (their own or in a lab) was a good one, its delivery is dry and retention is actually lower than straw house rates. The instructor-led, interaction offered in straw constructions (albeit “unofficial”) is still interaction and it, as well as hands on training, trumps merely reading and clicking any day.

Technicians attend most of the training grudgingly, as they know they contain key learning they’ll need to perform their functions and/or advance to the next level – but they take longer than necessary and aren’t as clear as they could be. The instruction is closer to a pre-training, focused on checking boxes, with the real learning happening afterward when technicians need to perform the task on-the-job. And, like straw training, that’s typically when training shortcomings are identified and can be demoralizing.

Technicians attend most of the training grudgingly, as they know they contain key learning they’ll need to perform their functions and/or advance to the next level – but they take longer than necessary and aren’t as clear as they could be. The instruction is closer to a pre-training, focused on checking boxes, with the real learning happening afterward when technicians need to perform the task on-the-job. And, like straw training, that’s typically when training shortcomings are identified and can be demoralizing.

Long-term retention is not the goal here though (at least it doesn’t seem to be), as there are periodic refreshers intended to keep technicians sharp. Each time they attend a training, they retain a little bit more, thanks to pure rote memorization. Brick house communities view rote memorization training as a form of torture, but more on that in the next post!

Six of one, half dozen the other? An ROI disconnect

Overall, the stick organization is neither pleased nor displeased with its training program and technicians are resigned to it as well. They find it adequate for their needs, keeping technicians aware of changing protocols and ensuring an acceptable level of compliance to them. And as the new training is developed at the behest of forward-thinking designers, eager to create technologically advanced brick structures, there’s a palpable energy. The hallmark stick organization inches forward, ever closer to leaving the sticks behind. It’s a slow process.

Stick house training is often solidly considered, but lax on design. This is mostly due to an ROI misunderstanding.

The operator error costs are lower at a stick-trained organization so the time spent on refresher courses feels justified, and why move beyond that? They figure the costs just continue to level out – with more money and time directed toward training, the operator error decreases in kind, and they always meet OSHA requirements (or whatever governing agency). A significant up-front expenditure to enter the brick house training ranks feels excessive to them. Unnecessary.

Stick house architects know why it is necessary though. They see the brick houses and know that operator error can be all but eliminated with the right training, but they have trouble communicating it to the building owner in a way that effectively addresses ROI.

They’ve performed solid needs assessments and understand their learning objectives, but are stymied when it comes time to design a new prototype to field test and iterate, as they’re stuck in the existing cycle. Unlike the straw house, the stick house folks are not allergic to change and do make gradual improvements, but are often bogged down with committee after committee tasked with making these changes. Stick training faces lots of red tape.

Identifying the stick structure & transforming

How do you know if you’re in a stick house training? This checklist will help:

__ Training employs CBT technology

__ Periodic training refreshers update content but not delivery

__ Research around new training methods possibly explored, but also ignored

__ Holding on to training that is outdated

__ ROI disconnect with conversations around diminishing returns

__ Training committee hindered by office politics

__ Operator error – and what to do about it – common theme in meetings

__ General consensus that advanced training options exist, but hesitant to consider/adopt them

Fortunately, the steps you need to take to move from a stick house to a brick house are largely cultural. That may sound awful to anyone familiar with stick house politics, but you’re in a much better position than straw house folks who need to prove the value of not losing fingers on top of it. Your stick house planners need to perform the same initial two steps as the straw folks (read that here) and then focus on design.

- Sorting out how this training should be created and delivered comes next. How has your training typically been designed and delivered? Perform a realistic audit of the experience and retention rates. What are the costs associated with every part of your training – from travel to equipment and technician time away from the job. Does it make sense to require the same CBT multiple times and depend on rote memorization? Considering those costs, what is the real cost of advancing to a brick house training?

- Prototype: Gathering all the requirements captured in the analysis, objectives and design phases and create a prototype of the training. You’ll likely contract with a designer for this step, but having a solid sense of what you want out of the learning – and key stakeholders working together toward the same goal on your training team – will help create an amazing partnership/final product.

- Field Test: Testing the prototype with a target segment. Have a small segment ready to put your training to the test, and provide them with an evaluation criteria template to inform their feedback and make it meaningful.

- Iterate: Take that feedback and make any changes necessary. Technicians may suggest small changes that will make a huge difference. Not every suggestion warrants a redesign, but it’s important to consider feedback in a brick house neighborhood – and that’s where you’re trying to move to.

Next you’re going to build and deliver the training – and, most importantly, evaluate impact. And this conversation is best suited for our brick training builders. We’re almost there – watch for that post next!