In 2015, Deloitte published a startling study, estimating two million manufacturing jobs would go unfilled in the next decade, but that number appears to have been too kind: “According to the most recent figures, 9.3 million Americans are unemployed, but 4.8 million jobs stand empty because employers can’t find people to fill them.” Why can’t we find workers to fill our skilled trades, and what can we do about it?

In 2015, Deloitte published a startling study, estimating two million manufacturing jobs would go unfilled in the next decade, but that number appears to have been too kind: “According to the most recent figures, 9.3 million Americans are unemployed, but 4.8 million jobs stand empty because employers can’t find people to fill them.” Why can’t we find workers to fill our skilled trades, and what can we do about it?

The answer is three-fold and requires a shift in how we educate, train and conduct business in the United States.

New opportunities, new education models

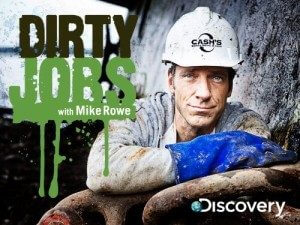

Mike Rowe seeks to “shine a light on America’s widening skills gap, and debunk the growing perception that “all the good jobs are gone.” And he’s right – according to the Department of Labor, America now has 5.6 million job openings and most of those 5.6 million opportunities don’t require a diploma – they require a skill.

Mike Rowe seeks to “shine a light on America’s widening skills gap, and debunk the growing perception that “all the good jobs are gone.” And he’s right – according to the Department of Labor, America now has 5.6 million job openings and most of those 5.6 million opportunities don’t require a diploma – they require a skill.

There’s a resurgence of manufacturing in the U.S. Combined with other factors, automation is bringing factories back to this country, as a robot is almost the same cost whether it’s in the U.S. or China. But technically skilled personnel are needed to operate, maintain and repair those machines, and they’re hard to find. “Millions of people who have stopped looking for work, are ignoring 5.6 million genuine opportunities.” Why? It starts in schools.

Education in the U.S. and Germany

In America, we’ve developed an aversion to technical training, relegating vocational education as a last resort and devaluing it as lacking in in the intellectual sophistication obtained by those pursuing a four-year college degree. As a result, “fewer than 5 percent of young people train as apprentices, the overwhelming majority in the construction trades.” European-style apprenticeships are different.

In Europe, they refer to it as “dual training” and it offers highly respected career paths in fields as diverse as advanced manufacturing, IT, banking, and hospitality. And these programs attract 60 percent of their youth. And why wouldn’t they? In Germany, job training looks very different, with students encouraged to pursue careers in trade. As a result, “Germany has one of the lowest youth unemployment rates in the world.”

Both employers and employees want more from an apprenticeship than short-term training. Our group heard the same thing in plant after plant: We’re teaching more than skills. “In the future, there will be robots to turn the screws,” one educator told us. “We don’t need workers for that. What we need are people who can solve problems”—skilled, thoughtful, self-reliant employees who understand the company’s goals and methods and can improvise when things go wrong or when they see an opportunity to make something work better.

Of course, we want skilled, self-reliant learners here as well. And one way to elevate how schools and learners view vocational education is through technology, specifically virtual reality. Not only does it offer that level of sophistication we assume is lacking in trades, but it enhances learning. Telling a student something offers a 10% retention rate, showing them is a bit better, and having them actually DO it via virtual simulation offers a 90% retention rate.

The ways it can be used are nothing less than stunning. New virtual reality experiences teach students how to repair cars, aircraft engineering, building maintenance skills, complete safety training in 3D, and so much more:

Doctors have been using VR to pinpointing ailments and assist in surgeries—by generating 3D models of real patient tumors from MRI scans. And science teachers use VR in biology and anatomy, where students need to grasp the inner workings of cells and organs that are not visible to the human eye. “Real organs used in dissection are preserved and inflexible, and the valves and muscle no longer pump,” Girard said. “I have been teaching biology for 22 years, and I have never had students understand the structures, relationships, and orientations of the organs with the same clarity as when they are viewed virtually.

Implementing this technology is expensive though, so it will require a partnership between schools and businesses.

Changing school and business training priorities

There are an estimated 30 million jobs that pay at least $55,000 per year and don’t require a bachelor’s degree in the United States. Communicating that out and transforming America’s apprentice program requires a “cultural rebuild” that’s already underway in California. They’re spending $6 million on a campaign to revive the reputation of vocational education, and $200 million to improve the delivery of it. The need for talent is a strong motivator, and businesses know that vocational schools can’t do it alone, and practice is essential.

Traditional eLearning and videos, which are what many rely on, are not effective for hard skill training because it’s mostly passive. There’s a lot of showing, but not much doing. Live sessions on the other hand, are expensive, hard to schedule and not scalable.

Developing simulated 3D interactive training applications, built on gaming technology, enables students to ‘Learn-by-Doing’ on their PC, Web, Tablet and AR/VR. And this helps students learn employable trade skills anytime/anywhere – skills that they can practice on equipment virtually. Businesses are employing this tech internally, with exceptional results. It’s time to move that training to schools with equal vigor.

Imagine an intra-company App store section for apprentices with Technical Skilled Trade Training – not focused on ‘paper degrees’ but actual employable skills. The library of apps would be modular and your team could expand on it every year – like an App store for the specific skills you need. It would ensure all new hires were trained to the same level of mastery on the same procedures and would enhance safety protocols as well. Most importantly, it would build a viable path to employable manufacturing related jobs, help close the skills gap and deliver a long-term ROI for your training budgets, and for the country as a whole. But where to start?

The First Steps

To have the most ‘force-multiplier’ effect, the focus should be building simulations for cross-company skills. A common example of a good starting candidate for many companies is the Lock Out/Tag Out (LOTO) Procedure.

LOTO is a safety procedure that’s used to ensure dangerous machines are properly shut off and not able to be started up again prior to the completion of maintenance or servicing work. It is universally used across industries as a safe method of working on hazardous equipment and is mandated by law in many countries. See how a user performs the steps here:

The 3D simulations should be built on the Three Pillars of effective learning methodology:

- SHOW you what to do (not TELL) in a virtual space that mimics the real world.

- Let you PRACTICE on your own as often as necessary, safely – from anywhere.

- Give simple, intuitive, language-neutral FEEDBACK (thumbs up or down, green or red checkmarks, etc.)

And it really is that simple. Once we get the ball rolling, companies could build these trainings in their App libraries, focusing first on ubiquitous trainings that would apply to a large portion of the company and updating them as needed, while creating additional trainings and eventually, an apprenticeship model rivaling what’s found in Europe. It makes sense from both a time and cost perspective. And the ROI is a given.

Again, from Mike Rowe: “As long as Americans remain addicted to affordable electricity, smooth roads, indoor plumbing and climate control, the opportunities in the skilled trades will never go away.” In fact, we’ve already seen demand increase. And with current technicians set to retire, we’re at a critical stage.

Are you ready to close the labor shortage gap in your company? Reach out today!