With recovery on the horizon and industries resuming operations, intermodal transportation is edging toward pre-pandemic levels. During the pandemic of 2020, many railroads have rethought their training protocols and have come to realize they can prevent, or at least significantly reduce, derailments with simulation training. Let’s see how that looks and why it’s just what the inspector ordered!

Derailment Dangers Always Present

Derailments are every railroaders’ nightmare, and preventing them is the foundation of every training and safety measure that railway workers are required to take. How often do derailments happen? In 2020 and so far in 2021, we haven’t seen many, but there’s also lots less traffic right now.

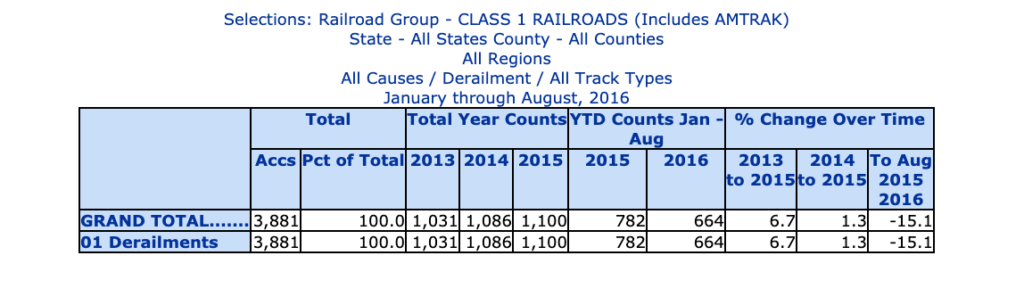

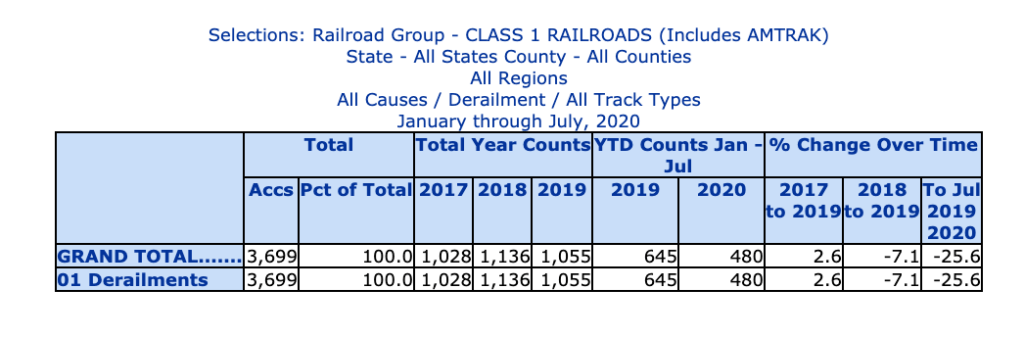

Gathering data from 2013, we can see that FRA Reportable derailments consistently number in the 650 to 1,100 range:

source: https://safetydata.fra.dot.gov/officeofsafety/publicsite/query/inctally3.aspx

And although a reduction in derailments for 2020 is amazing, it’s much less so when viewed in light of a pandemic that dropped railway traffic by 27% at its peak in 2020.

So, what causes these derailments? A variety of factors, including defects and rail conditions, , we know one thing about all of them: human error is typically the root cause. Saying as much oversimplifies a complicated series of actions though (many based on technical skills) – each of which offer lessons for preventing future catastrophes.

Simulating Human Error

How can simulation training prevent, or least greatly reduce, human error? By itself, it doesn’t. But with repeated application, it significantly enhances successful outcomes in a variety of ways. And that’s the key differentiator here: simulation training is available anytime, anywhere for repeated practice, check-ins and refreshers. And implementing that capability industry-wide will make these ‘human error items’ top-of-mind, potentially eliminating – and certainly lessening them.

We’ll demonstrate it using a couple of common errors as examples.

Inattentive Craft Employees, Due to Overconfidence

This particular challenge takes many forms. The first being overconfidence. In railroading, over-confidence is deadly. Craft employees that assume it’s a typical day and everything is fine can miss important indicators that their experience would have caught had they been laser-focused and in-the-moment. Simulation training can bring that overconfidence in line with reality.

For example, feeling a flat spot or riding over a broken rail. Should an employee miss how it feels when this happens? Certainly not – each creates a distinct sensation. But yet, they do miss it. How? It requires missing the flat spot during the pre-departure inspection, for starters – and then riding along assured that all is well.

Simulation training would drive home what the end result looks like when a flat spot is missed. It would simulate the severity of these mistakes, driving home how derailments happen ahead of having to experience one to understand.

Operating Switches

Operating Switches

Another inattentive craft employee scenario applies to any individual operating a switch. If a switch hasn’t been pulled all the way and locked properly, it creates a floating switch. Avoiding this should be a simple thing, but it happens. And again – overconfidence is to blame. And this could result in one part of car going down track one and the other down track two.

Simulation training would demonstrate how easy this is to miss; ways to make sure it’s truly locked in place and the life or death situations created when incompletely applied.

A scenario that is equally deadly and fairly common – but shouldn’t be is…

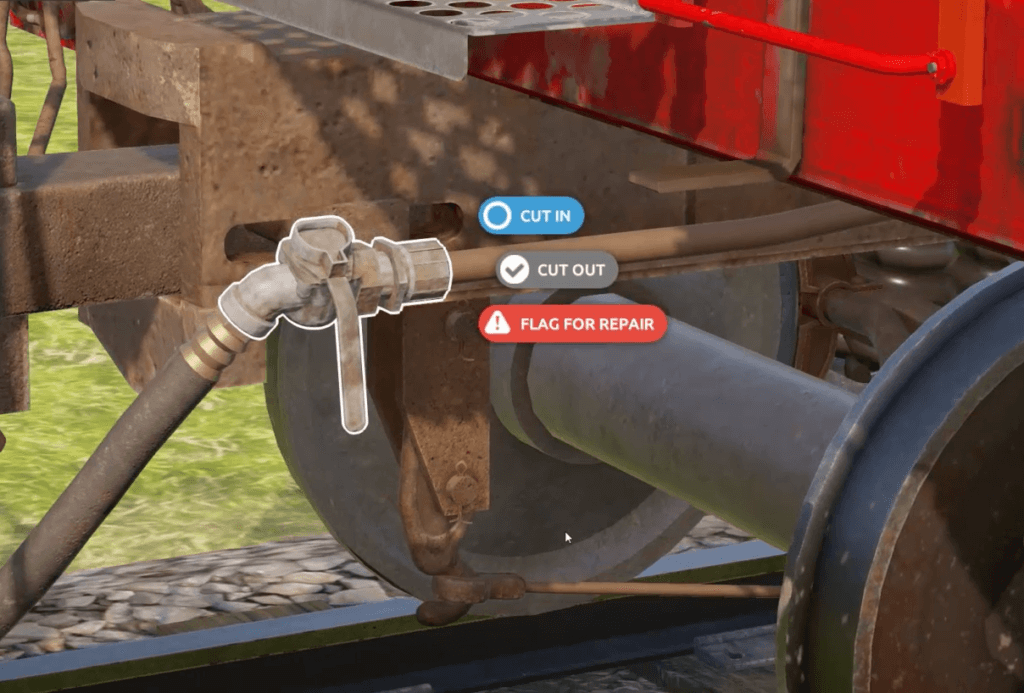

Cutout Cock & Retaining Valve Confusion

On freight equipment, a cutout cock is used to open or close air lines or to cut-in or cut-out air operated devices. When the handle is crosswise to the brake pipe, the cut-out cock is open. When the handle is in-line with the brake or other air lines, the cut-out cock is closed. This should be a simple thing to manage, but there’s a lot to keep track of on a train and having numerous “simple things” results in wrong choices. Or, in this case, misidentification for another simple thing!

On freight equipment, a cutout cock is used to open or close air lines or to cut-in or cut-out air operated devices. When the handle is crosswise to the brake pipe, the cut-out cock is open. When the handle is in-line with the brake or other air lines, the cut-out cock is closed. This should be a simple thing to manage, but there’s a lot to keep track of on a train and having numerous “simple things” results in wrong choices. Or, in this case, misidentification for another simple thing!

The Retaining Valve is often mistaken for a cutout cock. The Retaining Valve is a manually operated valve, found on all freight and some passenger cars, which controls the exhaust of brake cylinder pressure. And when an employee mistakes one for the other, this causes two different, and quite substantial problems.

- Closing the cutout cock instead of the Retaining Valve unknowingly cuts out air to the whole car. So, the train is moving along with no idea that the air is cut off. Good luck stopping.

- And applying the Retaining Valve instead of the cutout cock results in burnt up wheels – and when you break a wheel or crack it, derailments happen.

Capturing the Correct Expertise in a Training

The key here, of course, is ensuring that mechanical expertise is taught by mechanical experts; carmen teach other carmen and so on. This is not always the case in a training environment and it can prove deadly.

For example, if someone trained in the rudimentary functions of a craft, but no real experience working in the craft is teaching workers about it, they’ll probably do a decent job. It’s all related and they have some solid understanding of the function.

But because they have gaps in their knowledge, as they aren’t doing this as part of their day-to-day work, they can’t teach what they don’t know. They likely won’t know the sound or feel a mechanic is really looking for when examining something – and why.

Those working in that specific craft have developed a very attuned understanding of it and can offer tips that those who are not actively working in that craft on a consistent basis just simply do not possess.

With simulation training, railroads can capture that very specific expertise from those leading your mechanical (carmen), transportation (conductor and engineers), and engineering (Maintenance of Way, B&B, C&S) crafts. New hires and cross-training needs can be met in a way that offers the absolute best intel – virtual scenarios that train for in-the-moment life and death decision-making. It also helps create automatic reaction-time when faced with emergency scenarios in real life.

These are things regular classroom training cannot prepare workers for, and these are things railroads like BNSF, Union Pacific, Amtrak, CSX, Norfolk Southern, KCS, and others are recognizing as essential to encouraging enhanced, long-term safety. We provide a a variety of hazard-prevention training modules, and would love to share that knowledge with you.

Please reach out here.