How Railroads Are Using Simulations for OJT Training

Railroads are experiencing exceptional success using 3D simulations to enhance on the job (OJT) training, but the technology is often misunderstood. Allow us to pull back the curtain and share how and why these simulations are beneficial to every craft in your organization, from those leading the trainings to conductors, mechanics and carmen; as well as those maintaining the rails.

The primary goal of OJT is to ensure that workers in every craft meet or exceed mastery training levels. When these skills are found lacking, the goal shifts toward rapid remediation — and time is not on a railroad’s side when safety concerns are detected. Heading off these concerns is paramount, which brings us back to ensuring skill mastery is taking place in trainings for every craft. But is it?

Ensuring Every Craft Meets Mastery Training Levels

People are the most important element in any organization, and particularly where job mastery means the difference in life-or-death situations. And those scenarios can happen any day on railways as trains are in motion.

People are the most important element in any organization, and particularly where job mastery means the difference in life-or-death situations. And those scenarios can happen any day on railways as trains are in motion.

The people trained in each craft have a specific set of skills they’ve mastered and ensuring those skills match railroads’ expectations is essential. As it stands right now, there’s an apparent disconnect that has come to light.

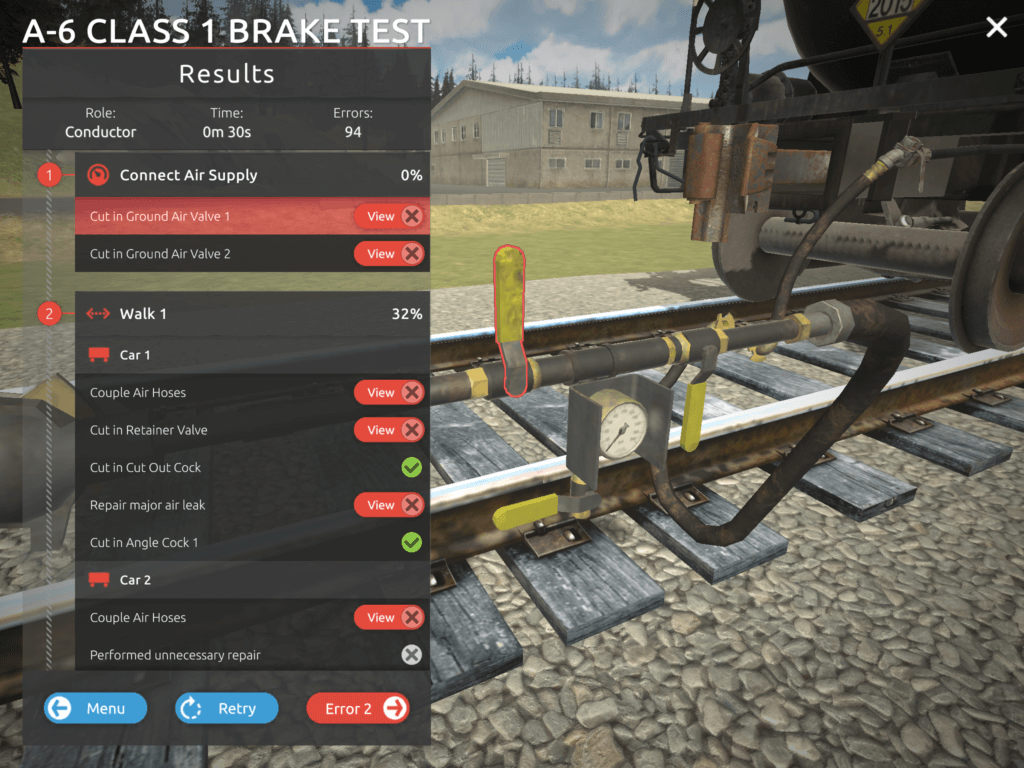

When implementing new trainings at railroads, we’ve uncovered a surprisingly high failure rate for workers new to 3D simulation training. This isn’t a case of mismatched training, but rather a series of gaps in workers’ collective knowledge. Workers have attained mastery for tasks they are failing when examined closely. This leaves railways ripe for the wrong mix of variables to make themselves known by way of a derailment or other safety incident.

This is not to say that the traditional training is insufficient, nor that a facilitator was lax in his/her responsibilities. Rather, it speaks to a previously unknown reality in the railroad industry overall – many workers are not trained to their optimal capacity. And this leaves the window open for mistakes that could be avoided with some additional, targeted attention.

Simulations as OJT Enhancements

As detailed in 49 CFR Part 243, the FRA wants to see proficiency measured via a formal training that is both complete and provides sufficient repetition. Today, considering staffing difficulties, everyone is stretched thin – and this includes setting aside the appropriate amount of time for training and that all-important repetition.

As detailed in 49 CFR Part 243, the FRA wants to see proficiency measured via a formal training that is both complete and provides sufficient repetition. Today, considering staffing difficulties, everyone is stretched thin – and this includes setting aside the appropriate amount of time for training and that all-important repetition.

Acting in tandem with PTC protocols and PSR, compliance waivers have helped railroads keep their essential infrastructure moving forward, as priorities shift toward leaner, more technologically sophisticated operations. And these challenges have actually helped railroads improve when it comes to training.

Interestingly, implementing simulation training type has identified critical knowledge gaps and allowed railroads to exceed training requirements and significantly enhance their safety profiles. This was an unexpected assist – one that is ushering in the next evolution in training protocols, which VR technology is destined to become a part of.

But how is this distinct from traditional training and where do training facilitators fit in this new mix? Speaking to the latter: trainers are still key – if anything, this mode highlights just how essential they are. We’ll explore why this is as we answer the first question below.

Simulation Training Differentiation & Facilitator Connection

Traditional OJT training happens in-person in large groups. And there’s an instructor leading by way of classroom instruction followed by a hands-on component. Each of these sections vary in length, ranging from hours to days. At the end of the training, the worker is considered proficient in said skill – but are they?

As mentioned above, railroads are realizing there’s a surprisingly high failure rate for workers new to virtual simulation training. They have somehow attained mastery for tasks that they have not fully mastered – not in the way railroads are intending.

With simulation training, each worker in each craft has a tablet with their specific virtual 3D instruction along with accompanying tasks they must perform on said tablets to demonstrate mastery. They cannot sit through a training and miss key elements, nor can they have someone sign off on training that may not have been supervised for the entire 8 hours it takes to complete. Workers must actively and repeatedly interact with their tablets and they cannot skip any bits of it without that omission attracting notice.

Also, training on a simulation allows all trainees to simultaneously participate, compared to traditional classroom interaction. More participation means more optimized time, allowing for enhanced training or more practice time. It’s also important to note that simulation training is more engaging than a typical computer-based training due to its interactivity and sophistication.

And this shines through in workers’ retention rates.

So, does this mean that instructors are no longer necessary? On the contrary, as none of this moves forward effectively without an expert in each craft reviewing workers’ tasks, as a nuanced understanding of specific actions will always be essential.

Beyond that, there will always be training materials to update – that part does not change. What does change is the time required to accomplish this task. Rather than spending weeks on tedious Word or PowerPoint updates, instructors submit change requirements to their technology provider who can quickly update the trainings for everyone by sending out a system update. Everyone is immediately apprised of new trainings and requirements and can be rapidly assessed for understanding.

Imagine how effective that would be in eliminating existing knowledge gaps? There’s really nothing left to imagine as it’s available and in use as many leading railroads today. Reach out at 888.781.0274 or [email protected] to see it in action and ways to tailor it to your specific processes.