Welcome to our recurring post, 3D Interactive Tech Talk, highlighting how interactive technology is being used right now and where it’s headed.

The Heat Is On

Learning the art of glass making is difficult, at best, and allows for minimal room for error, as furnaces can quickly reach temperatures of 1600 C (2912 F) and higher. Beatson Clark, a glass manufacturer in Rotherham, England, is employing the use of VRMT, a new Virtual Reality system, to assist new employees in learning the glass making process.

Learning the art of glass making is difficult, at best, and allows for minimal room for error, as furnaces can quickly reach temperatures of 1600 C (2912 F) and higher. Beatson Clark, a glass manufacturer in Rotherham, England, is employing the use of VRMT, a new Virtual Reality system, to assist new employees in learning the glass making process.

By working with a VR model of the factory, employees are able to train on complex machinery, and learn the glass making process up close. “Trying to learn the glass forming process from a book, or even on the shop floor, is difficult because the trainee cannot see exactly what is happening, so it takes quite a while to grasp.”

Trevor Phillips, a Production and Engineering Director for Beatson Clark, adds that the VR Training has an added benefit – “Because the virtual machine is highly visual the trainee becomes immersed in the program –rather like when you’re engrossed in a good movie – and it becomes easier to recall what has happened.”

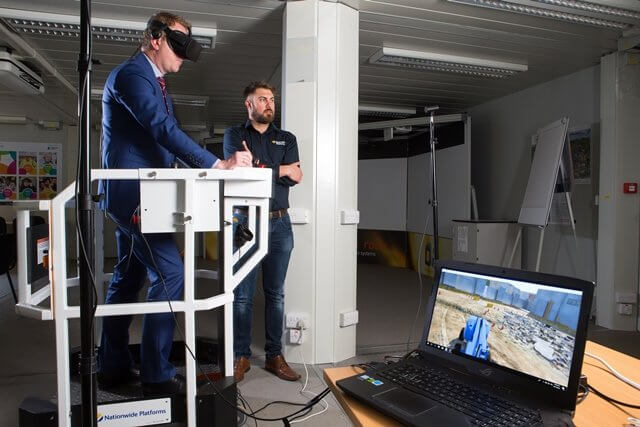

The viaducts that run under the M5, one of England’s busiest routes, have been under roadwork repair since January of 2017. As workers swap out 2.3 km of drainage, Nationwide Platforms has equipped the team working on the Oldbury section with Virtual Reality training simulators, the first of its kind in the UK, and has already trained 33 operators.

The viaducts that run under the M5, one of England’s busiest routes, have been under roadwork repair since January of 2017. As workers swap out 2.3 km of drainage, Nationwide Platforms has equipped the team working on the Oldbury section with Virtual Reality training simulators, the first of its kind in the UK, and has already trained 33 operators.

“Covering a range of applications – including familiarising themselves to different ground conditions, restricted access, overhead hazards as well as loading and unloading – the technology allows trainers to provide live feedback on operator skills and general operator behaviour, for safer operation.”

VR training allows workers to gain valuable experience, eliminate potential hazards, and reduces the possibility of accidents affecting life or property. According to BMV JV project director Nigel Fullam, “The collaboration shown by the whole project team to bring this training to the M5 demonstrates our commitment to continued improvement and challenging the status quo of traditional plant training.”

Do you have a question regarding this technology? Hit us up here now to discuss how this could apply to your needs.

And check out our virtual training solutions to see 6 real world case studies on how businesses are training their operations, maintenance, and field service teams.