Welcome to our recurring post, 3D Interactive Tech Talk, highlighting how interactive technology is being used right now and where it’s headed.

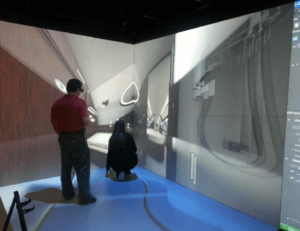

Gulfstream uses Immersive Reality for Maintenance Training

Gulfstream is enhancing maintenance training by leveraging immersive reality tools. With simulations launched through a virtual reality headset, the experience conveys the tactile, easy-to-use nature of Gulfstream’s newest flight deck.

Gulfstream is enhancing maintenance training by leveraging immersive reality tools. With simulations launched through a virtual reality headset, the experience conveys the tactile, easy-to-use nature of Gulfstream’s newest flight deck.

Gulfstream’s immersive reality tools also include the Gulfstream G650 and G650ER for maintenance training. Gulfstream’s Total Technical Training curriculum in immersive reality addresses several maintenance processes. Donning a virtual reality headset, visitors can remove cabin sidewall and flooring panels to reveal systems and experience interactive training processes that help promote safety and dispatch reliability.

Augusta Technical College Aviation Offers Virtual Simulator Instruction

Augusta Technical College’s Aviation Training Center houses two classrooms, six labs, and one virtual maintenance trainer (VMT). Department staff works together to provide cutting-edge instruction – using this Aerosim Boeing 737NG Virtual Maintenance Trainer. Instructor Joey Turner agrees: “It brings a new aspect to training for new students that are coming into the field, and it helps them to, again, be able to work under the FAA rules and regulations, just on a different type of aircraft.” Students say the virtual reality experience provides them with real-world knowledge and hands-on training.

Jon Jackson, an Augusta Technical College Aviation Student commented “The type of aircraft is not only a common aircraft, as far as large aircraft, a 737, but the realism of the simulation. The cockpit is exactly like the cockpit on the 737. The airframe is exactly the same. All the components, the wiring, so it gives you a very real sense of working on that particular air frame.”. It is exactly the exact replica of the aircraft that they are training on, so they can go straight from here from virtual world to a real world situation.

Study shows Maintenance Training ROI is highest

SMART ROI, a method for measuring the return on investment (ROI) of human capital processes such as engine maintenance training, can add millions to airlines´ net incomes each year, according to research and consulting firm Management & Excellence (M&E), which says studies it has carried out on major airlines around the world showed that three to six months of engine maintenance training can produce several thousand percent in returns.

SMART ROI, a method for measuring the return on investment (ROI) of human capital processes such as engine maintenance training, can add millions to airlines´ net incomes each year, according to research and consulting firm Management & Excellence (M&E), which says studies it has carried out on major airlines around the world showed that three to six months of engine maintenance training can produce several thousand percent in returns.

The main sources of financial returns are avoided off-wing engine maintenance, fewer delays and cancellations due to higher engine reliability, and higher efficiency in engine maintenance processes. “Some airlines we analyzed cut costs by $3 – 4 million per trained maintenance specialist in only three to six months after receiving line & base and Borescope training,” Dr. William Cox, CEO of M&E said at the 2017 World Aviation Training Conference and Tradeshow (WATS) in early May.

Do you have a question regarding this technology? Hit us up here now to discuss how this could apply to your needs.

And check out our interactive training applications to see some of the many ways businesses are benefiting from this technology.