Air Brake Test (CFR 232) – Interactive 3D Simulation

BACKGROUND & PROBLEM: Inspecting and testing rail car air brakes, a common railroad task, is a fundamental part of a railroad’s initial training for Conductors and rail car Mechanics. This inspection and testing, known as Class 1 Air Brake Test (CFR 232), requires railroads to have multiple rail cars on-site and allocate a significant amount of training time for demonstration, practices, and evaluation.

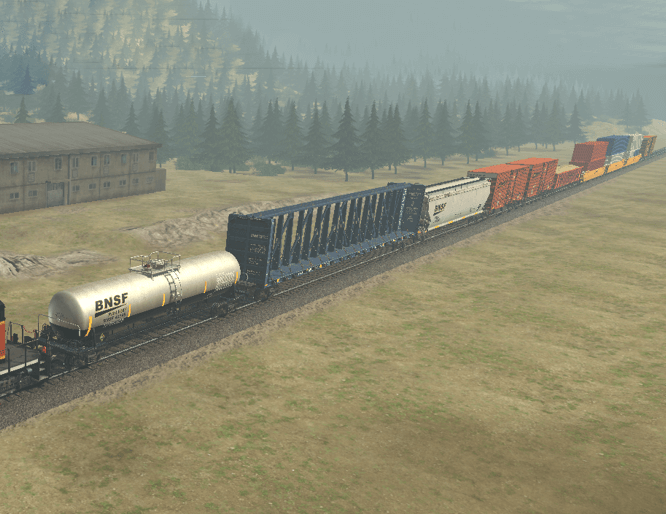

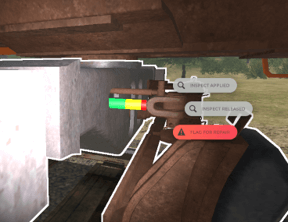

SOLUTION OVERVIEW: To alleviate physical space and time constraints, Railroads (BNSF, UP, CSX, Norfolk Southern, KCS and more) deploy simulation based training (by Heartwood) covering the complete inspection process. The simulation allows a student to visually inspect a variety of randomized rail cars, as part of a train, while manipulating brake components as necessary to properly configure the brake system. The student determines correct brake pressure and inspects for brake application & release via an exam practice mode. This gives the student additional practice at their pace, from any device, with a record of their performance given at the end.

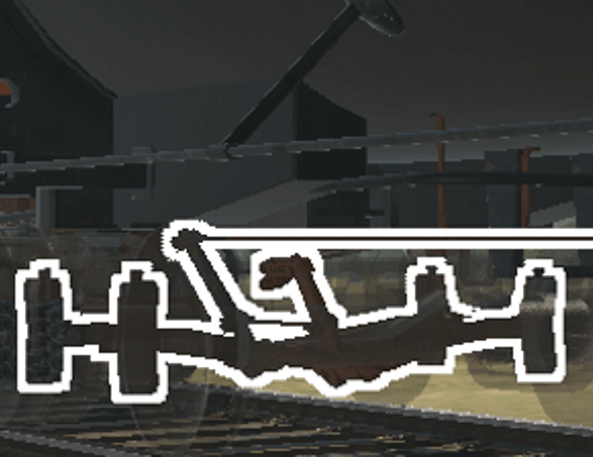

POSSIBLE DEFECTS

- Air hose leaking

- Uncoupled air hoses

- Piston leaking

- Angle Cock leaking or closed

- Retainer Valve leaking

- Cut Out Cock leaking or closed

- Fouled brake rigging

Complete list here.

CONSISTS