Daily locomotive inspections are required, and essential, when it comes to ensuring the safe operation of any railroad. And as railroads seek to continually enhance their safety protocols, they have turned to simulation-based training to offer technologically advanced and cost-effective options that will keep them on par with other intermodal transportation options.

With railroads that include BNSF, CSX and Norfolk Southern partnering with us to create a number of critical FRA compliant simulation trainings for functions spanning a variety of crafts, we understand what is at stake. And one crucial piece of a railroad’s everyday work includes daily locomotive inspections.

With railroads that include BNSF, CSX and Norfolk Southern partnering with us to create a number of critical FRA compliant simulation trainings for functions spanning a variety of crafts, we understand what is at stake. And one crucial piece of a railroad’s everyday work includes daily locomotive inspections.

Locomotives are in need of a daily inspection each calendar day they’re in use – and making sure these inspections are complete is important. Sometimes referred to as a Locomotive Calendar Day Inspection, it ensures that no safety hazards exist and that all components are functioning properly. Anything that could interfere with safe operation of the locomotive should be flagged during this process, as the inspector is ensuring that the locomotive meets all Federal Railroad Administration requirements (CFR 229).

When it’s not, the fines for noncompliance are significant. As detailed in Appendix A to Part 209—Statement of Agency Policy Concerning Enforcement of the Federal Railroad Safety Laws – there is a minimum civil monetary penalty per violation that can range from $892 to $29,192, with an aggravated maximum of $116,766. And, “FRA reserves the right to assess the statutory maximum penalty of up to $116,766 per violation where a pattern of repeated violations or a grossly negligent violation has created an imminent hazard of death or injury or has caused death or injury.”

So, to be sure that every part of this daily checklist is taken seriously, railroads offer rigorous training that is typically taught to inspectors using two complementary methods: PowerPoint presentations and hands-on training. This is a great way to learn, but railroads are realizing they can do better. As our railroading partners attest, adding simulation-based training processes enhances retention and saves railroads on a number of associated costs. Let’s explore!

Training Today

The in-classroom portion of today’s railroad trainings are led by a qualified instructor. And it offers a solid, visual overview of the process at hand. And this is followed up with a hands-on component, in this case – in an actual locomotive, to see each part of the daily inspection process in action.

These traditional modes of learning come with both logistical and learning challenges. And, as mentioned, there are significant costs associated with each challenge as well. We’ll explore each in turn.

Logistical Challenges

Although major railroads have training facilities and yards with locomotives available for training, the trainings themselves are challenging from a logistical standpoint.

Scheduling time and resources for trainings have associated costs. There’s the trainer’s time and the trainee to consider, as well. When one considers spending eight hours in class versus one hour on a simulation, the idea is intriguing. Or when considering sending workers to a week-long training and having them out of commission when you’re already operating with a tight crew rotation versus having them spend few hours locally on a sim that offers superior retention, the idea becomes crazy to not seriously consider.

And even if all of this did not pose too much of a hardship to schedule once, when remediation is required, those costs per employee are doubled. At least.

To alleviate physical space and time constraints, Railroads deploy simulation based training (by Heartwood) covering the complete inspection process.

Because with a simulation, and this locomotive daily checklist simulation specifically, students can visually inspect over 200+ items, giving the student additional practice at their pace with a record of their performance at the end. This is incredibly important when it comes to long-term retention – and long-term safety.

Learning Challenges: Long-term Retention & Safety

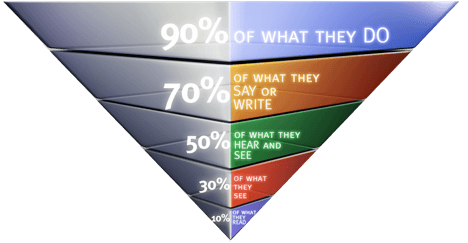

When a learner sees something written, they retain 30%. And when they see and hear it, their retention increases to 50%. If they then write it down, they’ll often achieve 70% retention, which is an admirable amount. And then, doing something is the most effective mode of learning, of course, with participants retaining 90%. But even 90% is not good enough when lives are on the line. So, how can brands enhance that 90% figure? By offering repeated hands-on opportunities.

When a learner sees something written, they retain 30%. And when they see and hear it, their retention increases to 50%. If they then write it down, they’ll often achieve 70% retention, which is an admirable amount. And then, doing something is the most effective mode of learning, of course, with participants retaining 90%. But even 90% is not good enough when lives are on the line. So, how can brands enhance that 90% figure? By offering repeated hands-on opportunities.

And this is where simulation-based training shines – and makes a significant impact on long-term retention. It’s available anytime, anywhere and meets learners where they are – each individual learner. It provides targeted, tailored training that ensures the trainee does not have any gaps in his/her knowledge. And increasing that retention from 90% to something approaching perfection.

It’s a lofty claim, for sure – but when inspectors in the shop or engineers in the field are retaining more, they’re using that knowledge to catch costly errors more often as well. Errors that could be missed otherwise and build over time to cause real problems. Typically, minor things that create big problems over time.

For example, a machinist, electrician, or pipe fitters work closely with locomotives every day and understand when something looks off. A new engineer, no matter how well s/he is trained, is at a deficit. They could know what to look for, but forget what, specifically is he looking at and miss something that would seem obvious to someone working on locomotives every day. The only thing that can combat that deficit is repeated practice. And that can’t happen every day at a training facility. It can, though, happen via simulation training. Anytime, anywhere, wherever and whenever it’s needed.

This Training, Specifically

What does this training cover? Beyond a user interface that allows the user to navigate and interact with 200+ inspection items, they are guided through multiple settings on lights and other switches and are guided to look for possible defects that are randomly generated in two visual states; “good” or “bad.”After using the sim, employees should be able to:

- Identify defective components on locomotives.

- Inspect wheels/trucks for defects.

- Identify safety hazards on locomotives.

- Measure locomotive components to determine if they meet requirements.

- Setup locomotive for operation including RCO setup and MU setup.

- Perform an Air Brake Test.

Trainees fill out a virtual inspection form during inspection and there’s an immediate scorecard that calculates performance and improvement stats. The full list can be viewed here. And the training itself is available on PC, iOS, Android, and on the Web via LMS/SCORM formats. Best of all? It meets FRA Part 243 training requirements.

Want the same results for your workforce? Reach out here – solutions@hwd3d.com or call 888.781.0274 ext. 701 to talk through specific questions and options to meet your railroad’s unique training needs!

View our complete Catalog of Rail Training Solutions available for your team to deploy today.