With hundreds of millions of dollars directed toward regulatory fines each year, it likely feels that these fines are a cost center that railroads just aren’t going to get rid of any time soon. But it’s one that can be slashed to a fraction of its cost – while adding a number of ROI wins. Let’s explore the potential.

With hundreds of millions of dollars directed toward regulatory fines each year, it likely feels that these fines are a cost center that railroads just aren’t going to get rid of any time soon. But it’s one that can be slashed to a fraction of its cost – while adding a number of ROI wins. Let’s explore the potential.

Normal & Willful Fines Don’t Have to be Inevitable

There are currently 36 different regulations sections for which the FRA could impose civil monetary penalties. And there are two kinds of penalties/fines that railroads face – normal/ordinary fines, levied against the railroad, and willful fines, which are directed to the individual worker for “willful” negligence.

Each civil monetary penalty (CMP) has a minimum and maximum range, which is adjusted for inflation every four years. And effective July 31, 2019, the minimum CMP is $892, the ordinary maximum CMP is $29,192. There’s also an aggravated maximum CMP that can reach $116,766. The severity of an infraction warranting a fine of this nature is extreme.

More specifically: If one is grossly negligent or demonstrates a “pattern of repeated violations [that] has created an imminent hazard of death or injury to persons, or has caused death or injury,” this aggravated maximum may be assessed.

And every day that a violation continues in operation (in-service), a separate CMP is assessed. So, it can get become exorbitantly expensive, very quickly.

Regardless of which standard applies, the fines for ordinary and willful violations are clear. And the FRA is not shy about assessing them. Nor should they be, as the accident/incident track record for the past decade is not optimistic.

Accidents/Incidents Are Trending Higher

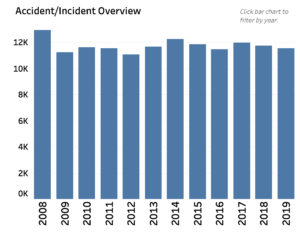

In 2019 alone, there were 11,545 accidents/incidents. And although we can see that number is a little bit less than 2018 (11,752), we can also see that the numbers are trending a bit higher in the past ten years overall:

In 2019 alone, there were 11,545 accidents/incidents. And although we can see that number is a little bit less than 2018 (11,752), we can also see that the numbers are trending a bit higher in the past ten years overall:

Comparing 2009 to 2019 specifically, the view is pretty compelling that something drastic needs to change:

And fines are certainly increasing as well. We see fines totaling $13,681,526 in 2018 and $16,510,228 in 2019. In fact, since 2013, we’ve been seeing a trend with fines increasing year-over-year. So, although recent years (from data above) may offer appearances of incremental improvement, the safety record when explored holistically is not.

And if it were, railroaders would experience a safer, more efficiently managed workplace. And the railroads themselves would benefit from greatly improved long-term ROI, spanning many indicators.

Here’s how that could look . . .

Simulation Training Saves Lives & Money

There are situations that railroads are unable to train workers for. Times when recreating an emergency scenario is either impossible or would place workers in too much danger.

For example, how should they react if a train hits a motor vehicle or if a derailment occurs due to failure to align a switch as required for movement? Talking about these scenarios does not prepare them in any real way when the time comes. But simulation-based practice can help make reactions to emergencies automatic. During an emergency, having any number of quick reactions running on autopilot can save minutes of indecision, at a time when minutes matter most.

The benefits of simulations are not exclusive to emergency scenarios – they serve as an incredibly effective learning retention tool for standard regulatory maintenance and safety protocols. See video below:

The more someone repeats an action, the better they remember it. And with individually tracked tests, identifying strengths and trouble spots is immediate – and immediately fixed. Workers can reassess and enhance their skills regularly, and the railroad can too.

And then there are the associated training costs to consider. Beyond saving railroads from significant fines, and lessening both violations and accidents to a fractional amount, railroads can train workers faster. So much faster. Training that would take days can be completed in hours. No travel or equipment costs to consider. Less time away from their job functions – See a sample FRA Waiver on using simulation as an alternative to satisfy the “hands-on” portion of periodic refresher training required by 49 CFR 232.203(b)(8).

Saving on the fines as “the icing?” This is truly the case, as the cake it envelopes contains so much more.

Savings & Training by Craft

In future posts, we’ll be exploring regulations by craft and ways simulation training can be applied to help railroads significantly enhance safety. And this conversation goes well beyond, “make a simulation training for it.”

- It details the very specific concerns each craft is faced with, focusing first on the most ubiquitous challenges, offering a realistic and impactful roadmap to resolving these concerns both in the short and long-term.

- It’s a way of both complying with evolving health requirements and accommodating shifting requirements in an intermodal world – one that (as railroaders know) does not sleep, nor slow down.

- And it’s a way to stay ahead of it all, while actually saving a significant amount of capital that’s currently lost to avoidable penalties.

Simulation training is the way railroads are headed – just watch BNSF, CSX, Amtrak, NS, UP, CN & KCS. Spanning Air Brake Test, Pre-Departure Inspection, Daily Locomotive Inspection and more, these railroads have made the leap to simulation-based training to enhance safety, logistics and boost long-term ROI.

If you have any questions about these Simulations & Guides, please reach out!